Engine Hoist and Lifting guide

Engine hoist is a tool that every professional car mechanic must have. But when it comes down to choosing the best tool for the job, people often get confused in the wide range of engine lifters. So to help and make this decision simpler, there is a comparison table just below with currently the most popular and best engine hoists on the market based on their quality, functionality and price.

On the table you will find different specifications about each hoist, such as their lifting capacity, hydraulic ram capacity, are they foldable, do they have extendable legs, number of adjustment positions of the boom and also our rating for the product.

| Product / Image / Purchase | Lifting capacity | Jack capacity | Foldable | Boom positions | Extendable legs | Our Rating |

|---|---|---|---|---|---|---|

| 3 tons (6000 lb) | (1) 12 tons (24000 lb) | No | 4 | Yes | 5.0 |

2 tons (4000 lb) | (3) 6 tons (12000 lb) | Yes | 4 | No | 5.0 |

|

| 2 tons (4000 lb) | (2) 8 tons (16000 lb) | Yes | 4 | No | 4.5 |

2 tons (4000 lb) | (2) 8 tons (16000 lb) | Yes | 3 | Yes | 5.0 |

|

2 tons (4000 lb) | (2) 8 tons (16000 lb) | Yes | 4 | No | 4.5 |

|

3 tons (6000 lb) | (1) 12 tons (24000 lb) | No | 4 | Yes | 5.0 |

|

2 tons (4000 lb) | (2) 8 tons (16000 lb) | Yes | 4 | No | 4.5 |

|

| 1 ton (2000 lb) | (4) 3 tons (8000 lb) | Yes | 4 | No | 4.5 |

1 ton (2000 lb) | (4) 3 tons (8000 lb) | Yes | 4 | No | 4.5 |

|

| 2 tons (4000 lb) | (2) 8 tons (16000 lb) | Yes | 4 | No | 4.0 |

What is an engine hoist?

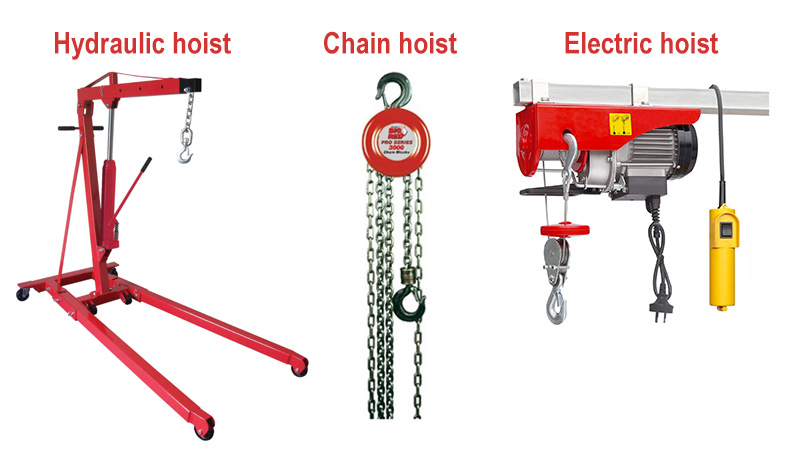

Engine hoist is a tool that is used for lifting engines and other car parts, such as an engine with a transmission out of a car. Engine hoist is just a name used to describe a tool that can be used in car repair works for engine lifting, but also can be used to lift heavy weights in other industries. This is why under a name – engine hoist, you will mostly find three types of hoists – hydraulic hoist, manual chain hoist and electric chain hoist. There also are pneumatic hoists that work with air pressure, but these tools are not that commonly used for engine lifting, although some hydraulic hoists also have pneumatic systems to automate the lifting process.

Different type of hoists have been used a lot back in the history to lift heavy loads, even before the first car engines were invented. These tools were called rope hoists which are predecessors of one of the most used type of hoists today – manual chain hoists.

Currently for engine lifting the most used type of hoists are hydraulic engine hoists which offer certain advantages over other type of hoists, so when someone is talking about an engine hoist, in most cases they will be referring to a hydraulic hoist. Hydraulic hoists have an all steel body, a large telescopic boom (usually extendable), legs with casters under them (so the hoist can be used on ground and does not need to be mounted anywhere above the engine or car), and a hydraulic jack that does the lifting part. Hydraulic jack uses a hydraulic oil to lift a load by increasing the pressure inside a cylinder. Manual chain hoist is built with multiple sprockets and gear system and lifts a load using a mechanical advantage, transforming small force over a long distance to large force over a short distance. Electric hoist uses a similar principle, but instead of an operator needing to manually pull a hand chain to lift a load, electric hoists are equipped with an electric motor for lifting a load.

As there lots of different types of engines which each has a different weight, starting from 200 pounds (90 kg) and less, up to few thousand pounds (few tons) for v10 and v12 engine blocks or engine blocks together with transmissions, there are engine hoists with varying capacities. For example, the most common lifting capacities for hydraulic engine hoists are 1 ton (2000 lb) and 2 tons (4000 lb), while for chain hoists they are even lower at 1/2 ton (1000 lb) and 1 ton (2000 lb). Those engine lifters that can lift over 3 ton and 4 ton (6000 lb and 8000 lb) heavy loads are made from more durable, higher grade steel materials, meaning that price for these tool usually is significantly higher than for regular engine hoists. The cheapest type of engine hoist is the manual chain hoist, which you can get below 100 dollars, after which follows the hydraulic engine hoist with price starting at 200 dollars, and the most expensive ones are electric chain hoists, with prices over 400 dollars for models with lower lifting capacities.

Next, we will look at each engine hoist type and their pros and cons in more detail.

Engine hoist types

There two more commonly used hoist types for engine lifting – hydraulic hoist and chain hoist, chain hoist also divides into manual and electric chain hoist. Here I will describe what each of these hoist types are, how they work, where they are mostly used and what are their advantages and disadvantages when lifting an engine.

Hydraulic engine hoist

What it is?

Hydraulic hoist is a type of hoist that uses hydraulic system for lifting loads. Hoist is made of a heavy duty steel construction and has got a hydraulic jack that does the lifting part of the tool.

Most hydraulic hoists have wheels below the tool, so they can roll across the floor which allows to use this type of hoist practically anywhere, the surface on which hoist can be used must be level and firm, so hoist does not start to sink in under a load.

Hydraulic hoists come with variety of lifting capacities, starting from 1/2 ton (1000 lb) up to 8 tons (16000 lb) and more, so they can be used not only to lift engines out of cars, but also for other lifting tasks in different industries. Price for engine hoists with lifting capacities of 1 ton (2000 lb) and below starts at approx. 200 dollars and goes up to few thousand dollars for high quality, industrial hydraulic hoists.

Today, most hydraulic hoists have foldable designs and can be fully disassembled. In early days engine hoists came as a whole unit, so it was very difficult to transport and it took a lot of space in a garage or a workshop. Today, because majority of tools can be ordered online, they can be fully disassembled for easier and cheaper shipping. Some may think that this impacts the durability of the tool, however in practice, if a hoist is stated to have a 2 ton (4000 lb) capacity, it should lift 2 ton heavy loads without any problems. Foldable design means that legs of the hoist can be lifted upwards and the boom can be lowered down to significantly reduce the length of the tool, allowing for easier storage when the tool is not being used. Changing the tool from working to folding position and back takes a very little time thanks to a quick and convenient locking pin system.

How it works?

The working principle of a hydraulic engine hoist is pretty simple. The most important part of the tool is the hydraulic jack. On engine hoists, hydraulic bottle jacks are used which are hydraulic systems that use hydraulic fluid (incompressible oil) pressure to lift and lower a load. The lifting is done manually, by inserting a special pumping handle into a socket at the bottom of the jack and pumping it increases the pressure inside the cylinder that lifts a ram to which an engines hoist’s boom is attached. At the end of the boom is a grab hook where load needs to be attached, so pumping the handle slowly lifts the boom and the load at the end. Lifting process is pretty slow because low amount of oil from a smaller cylinder is being pumped into a larger cylinder with each stroke. For lowering a load there is a bleed valve at the bottom of the jack which needs to be slowly opened to let the oil back from the cylinder to the reservoir and lower the ram and boom with the load.

Hydraulic hoists do not require a lot of maintenance, but there are few tasks that you need to be aware of. First, all moving parts of the hoist must be lubricated from time to time, so that the construction of the hoist works properly, but this is nothing new and must be done with all mechanical tools. You will need to pay more attention to the hydraulic jack, as it is the part of the hoist that does most of the work. Hydraulic jack will require oil change and air bleeding after certain period of usage. Both these maintenance works need to be done when the hoist doesn’t perform as it should, for example, not lifting load fully up or not being able to hold the load up after it has been lifted. Oil change and air bleeding are simple to do tasks and can be performed at home. Other than that, a hydraulic engine hoist should work for many years if maximum load limitation is not exceeded, with this routine maintenance needed after certain time.

Here is an informative video of how a hydraulic jack works

When talking about advantages and disadvantages of a hydraulic engine hoist in comparison to chain hoists, there are many reasons why you would choose to use a hydraulic hoist instead of other hoist types, which proves why hydraulic hoists are the preferred type of tool for engine lifting.

Hydraulic engine hoist advantages

- Lifting pace of a hydraulic engine hoist can be both an advantage and disadvantage for this tool, however, when compared to a manual chain hoist which is the second most used type of hoist for engine lifting, a hydraulic hoist is certainly faster and will allow to lift a load quicker.

- Hydraulic hoist, generally, have higher lifting capacities, meaning that if you need to work with very heavy weights, a hydraulic hoist is definitely the best choice for the task. Hydraulic systems can be found in many machines and tools that need to operate with extremely heavy loads, because hydraulic systems are powerful, precise, reliable and durable, and they are one of the best systems when it comes to handling heavy loads.

- The only area requirements for using a hydraulic engine hoist is that there must be a firm and level surface, so the hoist can be used on a floor indoors, on concrete or asphalt outdoors and even on a firm ground surface outdoors. Chain hoists, on opposite, must be hang over the car, which often requires to build a special scaffolding or even a trolley system for using the tool.

- Tool is pretty easy to operate once the hoist has been assembled. All engine hoists should come with usage instructions.

- Although a hydraulic hoist takes more space than a chain hoist, most hoists can be folded or fully disassembled for easier and more compact storage.

- Hydraulic hoist requires a little maintenance. Routine maintenance works consist of lubricating all moving parts from time to time, changing oil and bleeding air of the hydraulic jack when it does not perform as intended.

- Hydraulic engine hoists with larger lifting capacities over 1 ton (2000 lb) are cheaper than electric hoists with similar lifting capacities.

Hydraulic engine hoist disadvantages

- As mentioned, hydraulic engine hoists are pretty slow and will take you some time to fully lift a load, but in my opinion, waiting few minutes for lifting a load is nothing to be much worry about if the tool does its job as expected.

- Engines hoists with similar capacities have wide price gap, for example, you can purchase a hoist with 2 ton (4000 lb) capacity for 200 bucks or for 700 bucks. Cheaper hosts mostly have decent build quality and will lift according to their specifications without any problems, however, there might be exceptions when a hoist cannot be properly assembled, does not have all parts included in the package when ordered online, or requires additional upgrades for the tool to work correctly.

- Some hydraulic hoists come with unclear assembly instructions, so there might be some uncertainties when assembling the tool, but it should not take you a very long amount of time to assemble the tool. I recommend to assemble the tool by two rather than doing it by yourself, as it be much more quicker that way.

- If you have a very limited space in your garage or workshop, a chain hoist will take less space and can be hang over the workplace in opposite to a hydraulic hoist. But because most hydraulic hoists can be fully disassembled, I’m sure that everyone can find a place to store the tool while it’s not used.

- Hydraulic engine hoist will cost more than a manual chain hoist with similar lifting capacity.

Chain hoist

What it is?

Chain hoist is one of the most popular hoist types used for lots of lifting tasks, starting from lifting heavy equipment in shops and warehouses to lifting engine and other car parts in service stations. A chain hoist uses very simple gear system for lifting loads. Similar, but more primitive system called rope hoist has been used very far back in the history for lifting heavy loads. Chain hoists are so popular because of their ease of use and low price, considering the amount of weight such a tool can lift. Chain hoists have two types – manual and electric chain hoist. Manual chain hoists are a lot simpler and cheaper tools, they need to be operated manually by pulling a hand chain. Electric chain hoists, as the name suggests, use an electric motor to automatically lift and lower loads and the operator can operate the tool using an electric remote control.

Chain hoists need to be installed above the ground which greatly limits the number of areas this tool can be used. For example, if you want to use a chain hoist outdoors for engine lift, you will have to build some sort of a scaffold to hang the hoist. Also, many repairers build a special trolley system on their ceiling to allow moving the hoist with the load, because if your are lifting an engine out of a car, you either have to move the hoist with the engine away from the car so you can place it on engine stand for repair, or you will have to move the car away from the bottom the hoist. If you have a place to install such a system and have resources to build one, then an electric or manual chain hoist will make engine lifting an easy task in your situation.

When talking about capacities and price range of these type of hoists, manual chain hoists are the cheapest of all hoist types used for engine lifting. You can purchase a chain hoist with 1 ton (2000 lb) capacity for less than a hundred bucks. Manual chain hoists also can be bought in wide range of capacities, starting from smaller 1/4 ton (500 lb) up to 6 ton (12000 lb) capacity hoists. Electric chain hoists, in opposite, are a lot more expensive and models with lifting capacities over 1 ton (2000 lb) will cost even more than a hydraulic engine hoist. The price for an electric hoist with maximum capacity below 1 ton (2000 lb) starts at approx. 200 dollars and goes up to few thousand dollars for more advanced models.

How it works?

Chain hoists have a pretty simple structure and it uses gear system to lift loads. The construction of a chain hoist is made from a high grade steel. There are two chains on a manual chain hoist, one hand chain and one load chain, both chains loop the lifting mechanism. Hand chain sits on a wheel that is specially made with large grooves so that the chain does not come off the wheel in the lifting mechanism. When the hand chain is pulled, it moves a cog and an axle that goes trough the whole lifting mechanism and rotates a smaller sprocket at the end of the axle. Inside the lifting mechanism are multiple smaller and larger gears which turn a small force exerted over a long distance into a large force over a small distance, this is called a mechanical advantage, so when the hand chain is pulled, the force applied to move the large cog is multiplied many times throughout the lifting mechanism using gear ratio and at the end moves the load chain sprocket and the load chain. At the end of the load chain is a grab hook where a load leveler or a load can be attached using load chains or slings. To stop a load from falling down when the hand chain is not being pulled, chain hoists have a ratchet or braking system. Ratchet wheel prevents the load from lowering when the hand chain is not pulled, but allows to lower the load when the opposite side of the hand chain is pulled.

An electric chain hoists works in a similar way to a manual chain hoist, but instead of manually pulling the hand chain, an electric hoist uses an electric motor and is operated with a remote control, so electric hoist provides faster and easier way to lift and lower loads.

Video showing the lifting mechanism of a manual chain hoist

There are certain advantages and disadvantages for using a manual or electric chain hoist for engine lifting in comparison with a hydraulic hoist that I have listed below.

Manual chain hoist advantages

- The biggest advantage of using a manual chain hoist is that it is the cheapest way to lift an engine, they cost at lest two times less than a hydraulic engine hoist and multiple times less than an electric chain hoist, however, you need to have a place above the ground to mount the hoist and sometimes building such a structure will cost more than purchasing a hydraulic hoist.

- Manual chain hoists do not require electricity or other resources to operate. Also, the only routine maintenance work for a manual chain hoist is to regularly lubricate all moving parts of the hoist.

- These tools also come in large variety of lifting capacities which are suitable for engine lifting. You can get a manual chain hoist with up to 6 ton (12000 lb) capacity which is going to be more than enough for engine lift.

- Manual chain hoist are easy to operate, the operator needs to pull a hand chain to lift or lower a load and there aren’t practically no other mechanisms that need to be operated. The most difficult (and sometimes expensive) part of working with a manual chain hoist is to find or build a proper place to install the tool.

- Manual chain hoists take less space than electric hoists or hydraulic hoists, so if space is a problem in your workplace, then this hoist type might be the right tool to use.

Manual chain hoist disadvantages

- On some cheaper models the hand chain may come off the hoist when pulled. If this happens you need to take the metal cover that protects the lifting mechanism off the hoist and put the chain back on the wheel.

- Manual chain hoists are slower than electric chain hoist or hydraulic hoists, so you must take into account more time for lifting and lowering a load.

- Installing a manual chain hoist most of the times is much more difficult than setting up a hydraulic hoist. Chain hoist needs to be installed above the ground which usually means making a special ceiling mount or other type of installation. Also, if you want to use the hoist outdoors, you will need to make some sort of scaffold which can make the total costs of purchasing a hoist and building such a construction to use it larger than purchasing a hydraulic hoist.

- Manual chain hoists are great for lifting regular engine blocks, but if you need to lift something a lot more heavier, say a load with a 6 ton (12000 lb) or larger capacity, it is going to be easier to find a high quality hydraulic hoist for the job than a manual chain hoist.

Electric chain hoist advantages

- Electric chain hoists are the most easiest to use of these three hoist types thanks to the automatic lifting and lowering. The person operating the hoist can use an electric remote to control the hoist simply using buttons, no need to manually pump or pull a chain to lift a load.

- The fastest type of engine hoist when compared with hydraulic or manual chain hoists

- Electric chain hoists are tools for more professional use and will provide the most benefits for frequent lifting jobs when a lot of lifting needs to be done, for example, when working in a larger service station or specialising mostly for engine works. To improve usage of the tool, trolley systems are often built for electric chain hoists, allowing to move the hoist from one area to other.

- Electric chain hoists are fully automatic and the most of them also have high build quality which also means a higher price.

Electric chain hoist disadvantages

- Electric chain hoists cost significantly more than manual chain hoists and more than hydraulic engine hoists with similar capacities. For example, a chain hoist with 2 ton (4000 lb) lifting capacity may cost about 100 dollars, a hydraulic hoist about 400 dollars, while an electric chain hoist with similar capacity about 1000 dollars.

- If you want a cheaper electric chain hoist, you will need to put up with the low lifting capacities of cheaper models. Usually an electric hoist that costs around 200-500 dollars will come with lifting capacities of about 1/2 ton (1000 lb).

- Electric chain hoist needs an electric power source to operate while other hoists can be operated practically anywhere without need of other resources. This even more limits number of places an electric chain hoist can be used in comparison with hydraulic hoists or manual chain hoists.

Hydraulic engine hoist parts

The construction of most hydraulic engine hoists is very similar, only few details usually change as well as the quality of built materials used and maximum lifting capacities. An engine hoist consists of such larger parts as the main frame, hydraulic jack, legs, wheels, boom and a chain with a hook at the end of the boom. Depending on the hoist, it may have few additional supports for extra stability and durability such as support plates next to the main frame, or support for the boom. Next we will look at the most important parts of the hoist in more details.

Main frame

The part that holds everything together is the main frame or upright post. The frame, similar as other parts of hydraulic hoists, are made from a high quality steel tubes. These high grade steel tubes can handle very high load which is why more expensive hydraulic hoists can usually handle loads well over 2 tons (4000 lb). The main frame, as mentioned, can have two support plates on the sides depending on the model, which adds to the durability and stability of the tool. Also, some products may have a handle with rubber grips mounted to the top part of the frame, which allows to move the hoist easier when it is carrying a load.

Hydraulic jack

Hydraulic jack is the most important and advanced part of a hydraulic hoist that uses a hydraulic system to lift heavy objects. It generally is a hydraulic bottle jack that has one side mounted to the main frame and other side to the boom. Hydraulic jack has got a long cylinder with a ram and a pumping system that when operated pumps the oil from reservoir to under the ram, increasing the pressure inside a cylinder and that way lifting a boom and load attached at the end of the boom. Usually, hydraulic jacks have at lest few times higher lifting capacities than the maximum lifting capacity of the hoist to ensure that it works properly under higher loads. Hydraulic jacks come with a pumping bar that needs to be inserted into a special handle socket and pumped in order to lift a load. The same pumping bar has special grooves at the end which allows to turn the bleed valve easier for lowering a load. Some engine hoists have special mounts on the side of the upright post, where you can insert the pumping bar, so it does not lie around your garage floor while not being used.

Legs and wheels

Hydraulic engine hoists are equipped with two legs and 2-6 casters for most models. There are two types of engine hoists, ones that have expandable legs and ones that don’t, but you will find majority of hoists on the market to not have expandable legs. What are advantages of expandable legs? They provide better stability for the tool if, for example, the engine is located further into the engine compartment, so you need to lift it out with fully extended boom. Then you can also extend legs of the hoist and move them further below a car. Most engine hoists have foldable legs which mean that they can be lifted upwards when the hoist is not in use so it takes much less space when stored. Legs can be quickly folded using a quick release pin system and unfolded in the same way, meaning that you can change the hoist from working to folding position and back usually in under a minute.

Hydraulic engine hoists can have 2 or more casters under legs. Casters are used to transport the hoist and are made with durable steel bearings allowing to move the hoist also when carrying a load. You will find largest part of hydraulic hoists to have 4-6 casters, some hoist will have all swivel casters that can be fully rotated 360 degrees around, while others might have only rear swivel casters and regular front casters that can move only forward and back. The biggest advantages of swivel casters is that they increase the manoeuvrability of the tool which is great for those that have limited space in their workplace, but still need to transport the engine away from the car and place it on an engine stand next to the hoist. Hydraulic engine hoists need a firm and level surface, so wheels can roll freely on the surface and does not get stuck into the ground when lifting a load.

Boom, chain and hook

To lift a load an engine hoist has a boom. The construction of the boom is very similar for most engine hoists, however what differs between various models is if the hoist has an adjustable or regular boom. Today, you will find an adjustable or telescopic boom on most engine hoists which means that the boom can be extended to reach engine blocks located further into the engine compartment. Adjustable boom can have multiple adjustment positions, each with different maximum lifting capacity, however majority of engine hoists have 4 positions. For example, a 2 ton (4000 lb) engine hoist can have such positions: 2 ton (4000 lb) with closed boom, 1.5 ton (3000 lb), 1 ton (2000 lb), 0.5. ton (1000 lb) with fully extended boom. As you can see, by increasing the length of the boom, the maximum lifting capacity decreases. It is very important to know these limits before using the hoist, because else you can damage the hoist, the engine being lifted and it can also be dangerous to the person operating the hoist. Boom can be extended pretty quickly using a simple pin system. At the end of the boom is a steel chain with a grab hook, where you can attach the load.

Operating an engine hoist

Operating a hydraulic engine hoist is not a difficult task, but there are some important things you need to know, that’s why all engine hoists comes with an operation manual. For those that don’t have an operation manual, here we have covered the general steps for using a hydraulic engine hoist for engine lifting.

- Read the instructions – Always read the instructions before using an engine hoist. Engine hoist is a tool that operates with extremely heavy loads that can be dangerous not only to the load being lifted but also to the person operating the hoist. If for some reason you have lost the operation instruction of the tool, search for your product manual on the internet, as the most popular manufacturers usually place user manuals of their products on their website, or contact the manufacturer or seller directly. The following instruction is for general usage, but because different products have different specifications, all steps may not be applicable to your product.

- Inspect the hoist before each usage – Remember to carefully look at all parts of the hoist before each usage. Check for cracks and dents in the construction of the hoist, also check if the hydraulic jack does not leak oil, check the condition of mounting screw and pins. If anything is broken or damaged, replace the damaged part with a manufacturer recommended spare part or high quality aftermarket part.

- Also remember to do the regular maintenance for your tool – This includes lubricating all moving parts, changing oil and bleeding the hydraulic jack if it starts to fail when lifting loads.

- Free space around the hoist before lifting – make sure that there isn’t any objects blocking the engine hoist, as well as dust, oil spills or other debris on the floor where hoist will be used. Also make sure that the surface on which the hoist will be used is firm and level so wheels of the hoist move freely across the surface when carrying a load.

- Prepare the engine for lifting – remove all parts that are connected to the engine such as bolts tubes, wires and others parts, so the engine can be freely lifted out of the compartment. Also locate the attachment points on front, back, or on sides of the engine, lifting chains must be attached to these points using bolts.

- Prepare the hoist for lifting – check if the engine hoist is in a working condition and close the bleed valve if its is open. Place the boom over the engine that needs to be lifted, if boom must be extended in order to reach the engine attachment points, make sure that weight of the engine does not exceed the maximum lifting limit of an extended boom. If lifter is equipped with extendable legs, you can extend them to provide better balance when lifting an engine. Also remember to check if boom can be lifted high enough for engine to clear the engine compartment before setting up the hoist. If everything looks fine, you can attach the lifting bolts with lifting chains to the engine and connect other side to the grab hook or a load leveler. Also place an engine stand somewhere close the hoist, so you can store an engine for later repairs on the stand. You don’t want to leave the engine hanging on the hoist, as it is intended just for lifting purposes, not for long term storage of engines.

- Start lifting the engine – first, lift an engine just a bit to see if everything has been detached from the engine block and if engine is balanced and does not swing. If you see that engine block topples to one side, get a load leveler that will help to balance the load. Lift the load fully up so it clears the engine compartment by pumping the hydraulic pump using a pumping handle.

- Transport the hoist with and engine block away from the car – slowly transport the engine hoist with the load away from the car, pay attention that wheels of the hoist roll freely across the floor and make sure the load does not wobble around. Wobbling or swinging of an engine will increase the load to the hoist which can result in a failure of the tool.

- Lower the engine – hydraulic engine hoists can lower a load in much higher pace than lift it, so you must be very careful when lowering the engine. To lower a load, slowly turn the bleed valve counter clockwise using the end of the pumping bar. This process releases the oil out of the cylinder into the reservoir trough the bleeder valve.

- Store the engine on an engine stand – place the engine on an engine stand or other, previously set up place for further repairs.

Engine stand

Engine stand is a tool used to store an engine block, it allows to quickly install the block to the stand and provides useful features making repairs for the engine block much more convenient. Not only the engine stand is useful for storing an engine block while performing repairs to it, but also to store an engine block for extended periods of time, for example, if you are restoring a car.

Engine stands, similar as engine hoists are made from a durable, high grade steel tubes, so they come with storage capacities from 1/4 ton (500 lb) up to 2 tons (4000 lb) and more for advanced stands. Also, some engine stands are foldable, allowing to fold the top part or legs of the stand, decreasing its length and height for storage. Besides this, similar to hoists and other large tools, most engine stands come disassembled in a box if you order them online, so you will need to assemble the tool before usage. This should be an easy and straightforward task that can be done by a single person, as weight of most engine stands is much lower than for hydraulic engine hoist. Also, each engine stand should come with installation instructions, but if they are not included, you can check online for one or use instructions of other, similar type engine stand, as the construction of most of these tools is akin. When talking about the price range of engine stands, you can get the most basic models with about 1/4 ton (500 lb) capacity at approx. 50 dollars, larger 1/2 ton (1000 lb) models will cost over 100 dollars and more advanced stands with higher storage capacity over 1 ton (2000 lb) will cost around 200 dollars. Not all engine stands are similar and there can be few variations in parts used on the stand, so next we are going to look at different parts an engine stand is build from and how these parts refer to the operation of the stand.

Upright post and base post

The backbone of an engine stand is the upright post. This is the part of the stand that holds everything together – the head part that consists of rotating and mounting mechanism and the bottom part consisting of leg (or legs) and casters. The upright post, same as other parts such as the base and legs are made from durable, hight tensile steel tubes, the thickness of these tubes depends on the overall quality and maximum storage weight, so it varies across different products. Under the upright post is the base post which connects to both legs (if stand has got two legs) or is used as a leg and has got casters at both ends on stands with a single leg construction. Some stands also have braces at sides of the upright post for additional durability and stability of the tool.

Legs and casters

The design of an engine stand differs depending on the storage capacity of the tool, this is why you will find engine stands with 1, 2 or 3 legs. Stands with 3 legs are the rarest and are used only on stands that support a specific type of engine. Much more common are engine stand with 1 or 2 legs. There are two types of single leg stands – with either 3 or 4 casters. Single leg stands with three casters are the most basic ones that can support smaller engine blocks with low weights. Usually these stands have maximum storage capacities of 500 – 750 lbs, but in reality cannot hold engine block much heavier than 300-400 lbs. Single leg stands with 4 casters, on the other hand, are much more stable and can support loads even up to 1500 – 2000 lbs or 1 ton. For larger and heavier engine blocks, stands with 2 legs are used, these usually have either 4 or 6 casters. Some engine stands have all swivel casters meaning that wheels of the stand can be turned in any direction, extending manoeuvrability of the tool. Other stands might only have front swivel casters, while some will come without swivel casters, so they can only be moved forward and back. Also, there are engine stands with foldable leg or legs that can be quickly lifted upwards using a quick release pin system, this decreases the overall length of the tool and allows for easier storage.

Rotating mechanism

On top of the engine stand is the head that consists of a rotating mechanism, rotating handle or gearbox, head plate and mounting arms. The rotating mechanism allows to rotate the engine block stored on the stand 360 degrees around. On top of the head there is a hole with a locking pin that allows to fixate the head of the stand in multiple positions, allowing to turn the engine block to a position that is easy to access for repairing the engine. For easier turning of the head and the engine block there is a handle on the rear of the stand, it is a long steel bar with one or two rubber grips at sides. Some stands have more complex gearbox mechanisms that allow to rotate the engine block much easier using their built in rotating mechanism. More advanced engine stands even have an automatic rotating mechanism which allows to rotate the engine block faster and more convenient.

Head plate and mounting arms

The part where engine block connects to the stand is called a mounting arm. An engine stand has 4 of these mounting arms and they can each be adjusted to fit different engines. These arms are connect to a head plate that rotates together with the rotating mechanism. Some engine stands come with mounting screws to attach the engine block to the stand, however, different engine blocks require different length and durability screws, so you will probably have to buy them separately to fit your specific engine block.

TOP5 engine hoists

Dragway Tools 3 ton engine hoist

Specification

- Maximum lifting capacity – 3 tons (6000 lb)

- Hydraulic jack capacity – 12 tons (24000 lb)

- Foldable – No (dismountable)

- Extendable legs – Yes

- Weight – 325 lb (147 kg)

- Dimensions (dismounted) approx. – 30x57x65 inches (76x145x165 cm)

Review

This engine hoist is manufactured by a company called Dragway tools which is one of the best known lifting tools manufacturer. The hoist can lift loads up to 3 tons (6000 lb) which is at least a ton (2000 lb) higher than an industry standard, so this tool will be the best suited for those that need to lift very high loads. Dragway Tools LD-3013 engine hoist not only has a high capacity with closed boom, but also can lift loads with weight up to 1 ton (2000 lb) with fully extended boom which is incredible, as some engine lifters have similar maximum lifting capacity with closed boom.

To be able to lift such high loads this tool has the highest grade steel construction. Dragway Tools 3 ton engine hoist has got a premium quality steel frame with 2 support plates on the sides for extra durability of the tool. The hoist not only is great on the paper, but also looks decent in real life, all welds have been worked till the end and just by looking at the hoist you can tell that it will last for many years of use. There is a mount for the pumping handle on the side of the hoist, so the pump does not lay around the floor at your workshop while not used. The only thing this engine hoist lacks is a pushing handle at the back of the frame, but this is not a major disadvantage that would impact the durability or the quality of the tool. If you really need a pushing handle, you can make and mount one by yourself pretty easily by using a steel bar and two rubber grips at the ends.

The lifting of Dragway Tools engine hoist is done by a high capacity hydraulic jack. We have used to seeing hydraulic jacks with 8 ton (16000 lb) capacity mounted on most hydraulic hoists, but because of the high total lifting capacity, this tool has got a 12 ton (24000 lb) capacity hydraulic jack that can handle practically any task you throw at it. The operation of the jack is similar to other hydraulic engine hoists, lift a load by pumping the handle and lower it by releasing the bleed valve.

Whole construction holds on two steel legs. Both legs of this hoist can be extended from 55 inches (139 cm) to 89 inches (226 cm), so you can get an extra stability when lifting loads located further into engine compartment. To provide better durability both legs of the hoist cannot be folded, but as the hoist comes dismounted, you can always disassemble the tool if you won’t need to use it for some time and don’t have enough space for storing the tool in a working position. Under both legs there are total of 4 casters, 2 on the front and 2 on the back. On the front there are 2 larger 6 inch casters that can only be moved forward and back. On the back the hoist has 2 smaller 4 inch swivel casters that can be rotated 360 degrees around for extended manoeuvrability.

Dragway Tools hydraulic engine hoist also has got an extendable boom with 4 extension positions:

- 3 ton (6000 lb) with boom length of 55 inches (139 cm);

- 2 ton (4000 lb) with boom length of 60 inches (152 cm);

- 1.5 ton (3000 lb) with boom length of 68 inches (173 cm);

- 1 ton (2000 lb) with boom length of 75 inches (191 cm).

The lifting range from the floor to the bottom of the hook is 72 inches (182 cm) with closed boom or at 3 ton (6000 lb) position and 84 inches (213 cm) with fully extended boom or at 1 ton (2000 lb) position. The hoist also has got a steel chain and a forged steel hook at the end of the boom for attaching the load with a load leveler or lifting chains.

Advantages

- Higher lifting capacity than most other engine hoists, 3 tons (6000 lb) with closed boom and 1 ton (2000 lb) with fully extended boom

- Premium quality steel frame and parts

- Extendable legs for extra stability when lifting loads with extended boom

- High capacity 12 ton (24000 lb) hydraulic jack

Disadvantages

- Does not have a foldable design

- Does not have a pushing handle for easier movement of the hoist under load

- Only 2 swivel casters from 4, limits manoeuvrability of the tool

Strongway 2 ton engine hoist with load leveler

Specification

- Maximum lifting capacity – 2 tons (4000 lb)

- Hydraulic jack capacity – 6 tons (12000 lb)

- Foldable – Yes

- Extendable legs – No

- Weight – 184 lb (83 kg)

- Dimensions (folded) approx. – 29x30x61 inches (74x76x155 cm)

- Dimensions (working) approx. – 65x40x52 inches (165x101x132 cm)

Review

Hydraulic engine hoist is manufactured by a company called Strongway, their tools always have good build quality and are durable for all sorts of lifting tasks. This particular engine hoist has a maximum lifting capacity of 2 tons (4000 lb) which will be enough for majority of engine blocks, but it can also be used to lift other car parts such as transmissions and gearboxes. What makes this tool unique is that it comes with a load lever which is a must have tool for all lifting jobs, this means that you won’t need to purchase it separately. The load leveler has got a 3/4 ton (1500 lb) capacity which is a little lower than the maximum lifting capacity of the engine hoist, but should still be good enough for lifting most engine blocks.

The frame of the Strongway 2 ton engine hoist is made from a heavy duty steel to grant durability for the tool. The product comes dismounted in a box, so you will have to assemble it. Assembly instruction are included with the product, I suggest getting another person to help you assemble the tool as that significantly speeds up the process, however, the tool can also be assembled by a single person. There are 2 support plates on the sides of the main post for added durability. Strongway engine hoist features a foldable design, you can lower the boom and lift the legs of the hoist to decrease its length by more than 30 inches (90 cm) which is useful for storing the tool. As a nice addition is the pushing handle with two rubber grips behind the main post and a holder for the pumping handle on the side of the frame.

The lifting on Strongway 2 ton engine hoist is done by a heavy duty 6 ton (12000 lb) hydraulic jack. The bottom of the jack is installed to the main post and the top of the ram installs under the boom and is lifted upwards when the jack is pumped, also lifting the boom with the load attached to it. Hydraulic jack used on this hoist has got a good quality, but regular maintenance will be needed to ensure that the jack works properly, such as changing the oil and bleeding the air out of the jack.

Under the hoist are 2 foldable legs with 6 casters. Both legs are made form the same durable steel material as the main post. Legs can be folded upwards using simple quick release pin system which works by taking out two pins that attach legs to the hoist’s frame, lifting legs in an upward position and placing pins back into special mounts on the bottom part of the hoist. To transform hoist into working position simply do the previous steps in a reverse order. All 6 casters of the hoist have durable steel bearings and can be rotated 360 degrees around for extended manoeuvrability.

Strongway hydraulic hoist is equipped with an extendable boom with 4 adjustment positions:

- 2 ton (4000 lb), 36 inch (91 cm) length;

- 1.5 ton (3000 lb), 42 inch (106 cm) length;

- 1 ton (2000 lb), 49 inch (124 cm) length;

- 1/2 ton (1000 lb), 55 inch (139 cm) length.

The lifting range with a closed boom or at 2 ton (4000 lb) position is 70 inches (1.78 meters) and with fully extended boom or at 1/2 ton (1000 lb) position – 82 inches (2.1 meters). There is also a steel chain and a grab hook at the end of the hoist, where the load leveler is attached. The load leveler allows to easily balance the load lifted by turning a screw that connects both sides of the leveler. I recommend to use a load leveler always when lifting engine blocks or other heavy loads, because you don’t want the load to start wobbling or swinging, especially when lifting with an extended boom, because it increases the load on the hoist and can damage the tool.

Advantages

- High quality steel construction and parts

- Stable tool that is easy to move thanks to 6 swivel casters and a pushing handle

- Comes with a 3/4 ton (1500 lb) load leveler which is used to balance the load and is a must have tool for lifting heavy objects such as engine blocks

- Foldable design is useful for storing the tool

Disadvantages

- A bit pricier than couple other 2 ton (4000 lb) hoists with very similar design

Torin T31002

Specifications

- Maximum lifting capacity – 1 ton (2000 lb)

- Hydraulic jack capacity – 3 tons (8000 lb)

- Foldable – Yes

- Extendable legs – No

- Weight – 165 lb (75 kg)

- Dimensions (folded) approx. – 63x16x8 inches (160x40x20 cm)

- Dimensions (working) approx. – 52x44x57 inches (132x112x145 cm)

Review

Torin Jacks is one of the best known manufacturers of automotive equipment in the USA that also produces various engine hoists. This Torin T31002 is one of the best selling 1 ton (2000 lb) engine hoists on the market, because it has got a high built quality and is also very durable. The hoist can lift up to 1 ton (2000 lb) heavy loads which will suit most v4 and v6 engine blocks. For lifting larger and heavier engines, I suggest looking for a 2 ton (4000 lb) engine hoist.

Torin hydraulic engine hoist features a foldable design and can be folded as small as 63x16x8 inches (160x40x20 cm) which is impressive when compared with larger 2 ton (4000 lb) hoists. This is great not only for storage but also for transportation, also the hoist weights just 165 lb (75 kg) which is a pretty small weight for an engine hoist. If you need to work mostly with smaller engine blocks and have a tight space in your garage or workplace, I suggest that you get one of these 1 ton (2000 lb) engine hoists.

Although it only has a maximum lifting capacity of 1 ton (2000 lb) it is still made from a very high quality, heavy duty steel. You can see the same quality on each part of the hoist, starting from casters to the hydraulic jack and the boom of the hoist. Behind the hoist is a push handle with two soft rubber grips that helps to move the tool more easily under load. Also, on the side of the main post is a holder for a pump handle.

The lifting is done using a 3 ton (6000 lb) hydraulic jack. This hydraulic jack operates using a pump handle which needs to be inserted into the socket at the bottom of the ram and pumped to lift a load. Lifting a load is quite slow process, similar as with other hydraulic engine hoists. To lower a load simply open the release valve at the bottom of the jack, but remember to be very careful when opening the valve, as the load will drop quickly, just a small turn at a time. Overall, this is a good quality hydraulic jack that should provide a trouble free lifting.

Torin T31002 hydraulic hoist has got 2 legs and 4 casters under the legs. Both legs can be folded for easier storage using a quick release pin system. Legs can also be removed from the hoist if the tool needs to be transported. 4 steel casters move freely even under a load. Front casters are fixated into the legs of the hoist and can move only forward and back, while on the back are swivel casters that can be rotated 360 degrees for increased manoeuvrability.

Torin T31002 engine lifter has got an extendable boom with 4 adjustment positions:

- 1 ton (2000 lb);

- 3/4 ton (1500 lb);

- 1/2 ton (1000 lb);

- 1/4 ton (500 lb).

The lifting range of the hoist is 78 inches (2 meters) from the ground. At the end of the boom there is a steel chain and a grab hook where you can attach the load leveler or load directly.

Advantages

- High quality, durable steel frame and parts

- Folds to very small dimensions, smaller than practically any 2 ton (4000 lb) engine hoist

- Easy to assemble thanks to the small size

Disadvantages

- This hoist is not as stable as hoists with 6 casters

- Very high price for a 1 ton (2000 lb) hoist

Dragway Tools 2 ton engine hoist

Specification

- Maximum lifting capacity – 2 ton (4000 lb)

- Hydraulic jack capacity – 8 tons (16000 lb)

- Foldable – Yes

- Extendable legs – No

- Weight – 165 lb (74 kg)

- Dimensions (folded) approx. – 59x36x22 inches (150x92x56 cm)

- Dimensions (working) approx. – 65x41x37 inches (165x104x94 cm)

Review

Dragway Tools company makes few of the highest quality engine hoists on the market and this tool is no exception. Dragway Tools LD-3012 is one of their best selling models, because it features both – high build quality and affordable price. The hydraulic engine hoist has got a lifting capacity of 2 tons (4000 lb) which will suit engines with different sizes and weights. Thanks to the great value, this engine hoist has earned good reviews from many users.

The hoist has got a foldable design, it can be quickly transformed from working to folding position and back using a simple pin system also seen on other engine lifters. The whole construction of the hoist is made from a high quality 0.31 inch (7.8 mm) steel and is one of the most solid frames for engine lifters at this price range. From legs to the main post the to boom, the construction of the tool has got high quality and can easily hold up to 2 ton (4000 lb) heavy loads. The hoist also has 2 support plates on both sides to increase the durability of the tool. Same as with other lifters in this TOP, Dragway Tools LD-3012 hoist has got a holder for the pumping handle on the side of the post. Unfortunately, there isn’t a pushing handle at the back of the hoist.

To lift a load the hoist is equipped with a high capacity 8 ton (16000 lb) hydraulic jack. This is a strong jack that can lift loads heavier than 2 tons (4000 lb) without any problems, you can expect a long work life from this jack. The hydraulic jack on this Dragway Tools 2 ton engine hoist works the same way as other manual hydraulic jacks, pump the handle to lift a load, release the bleeder valve to lower a load. However, Dragway Tool also makes another 2 ton engine hoist that is equipped with a hydraulic jack with an air pump mechanism that is used to lift loads automatically using an air pressure, so you don’t have to manually pump it with a pumping handle. If you are interested, you can check out a review of the hoist here.

The construction of the hoist sits on two steel legs. These legs can be folded for storage using the quick pin system to decrease the total length of the hoist. Both legs are made form the same steel material as the main post, but in a 0.125 inch (3.2 mm) thickness. Under legs there are total of 6 swivel casters, which means that each of the casters can be rotated 360 degrees around. This tool is very easy to manoeuvre and also is very stable thanks to those 6 steel casters under the hoist.

On top the Dragway Tools engine hoist has got an extendable boom with 4 positions:

- 2 ton (4000 lb);

- 1.5 ton (3000 lb);

- 1 ton (2000 lb);

- 1/2 ton (1000 lb).

The lifting range with closed boom or at 2 ton (4000 lb) position is 48 inches (1.22 m) from the ground and with fully extended boom or at 1/2 ton (1000 lb) – 102 inches (2.59 m) from the ground. There is also a steel chain and a grab hook at the end of the boom where you can attach the load.

Advantages

- Durable, high quality steel construction and parts

- Very stable under a load, thanks to 6 casters

- Easy to move and manoeuvre because of all swivel casters

- Good price for a 2 ton (4000 lb) engine hoist

Disadvantages

- No pushing handle at the back of the frame

- The assembly instructions of the tool could be improved

Best Choice Products 2 ton engine hoist

Specification

- Maximum lifting capacity – 2 ton (4000 lb)

- Hydraulic jack capacity – 8 tons (16000 lb)

- Foldable – Yes

- Extendable legs – No

- Weight – 160 lb (73 kg)

- Dimensions (folded) approx. – 31x29x50 inches (78x73x127 cm)

Review

If you have searched for an affordable engine lifter, you have probably came across this tool sold by Best Choice Products. This is their hoist with a 2 ton (4000 lb) lifting capacity that can be used to lift engines, transmissions and other car parts as well as heavy loads in other industries. This is quite a popular engine hoist, despite the less known manufacturer when compared to other hoists in our TOP. The popularity of this engine hoist mostly comes because of its cheap price, being one of the cheapest 2 ton (4000 lb) engine hoists on the market but still packing some useful features as well as pretty decent build quality.

Best Choice Products 2 ton engine hoist is made from a high tensile 1/4 inch thick steel. The construction of the tool is pretty durable and should not have problems lifting up to 2 tons (4000 lb) heavy loads. On the side of the main post are 2 support plates for extra stability and durability. The hoist also features a foldable design meaning that you can lower the boom and fold legs of the hoist so it takes up less space when stored, in a very similar way to other 2 ton engine hoists. This lifter, however, does not feature a pushing handle that allows to move the hoist easier under load.

Best Choice Products 2 ton engine hoist uses a hydraulic jack to lift a load. This particular tool is equipped with a high capacity hydraulic jack that supports weights up to 8 tons (16000 lb). This is not the best hydraulic jack I have seen on an engine hoist, but it does its job and should not cause much problems when lifting loads. You will need to perform regular maintenance for the jack such as changing oil and bleeding the jack which both are pretty simple to do tasks at home, they should be done when you start noticing that the hoist is failing to lift or hold heavier loads. Other than that, the jack should perform well even under high loads.

This lifter is equipped with 2 steel legs, both legs can be folded using safety pins for storage. As the hoist comes dismounted, you can also take the legs of the hoist completely off, if for example you need to transport the tool or have a very tight space in your workplace for storing the hoist. Best Choice Products engine hoist has got 6 casters, all 6 are swivel casters so they can be turned fully around, allowing to move the hoist in practically any direction.

The engine hoist is equipped with an extendable boom with 4 positions:

- 2 ton (4000 lb);

- 1.5 ton (3000 lb);

- 1 ton (2000 lb);

- 1/2 ton (1000 lb).

The lifting range with a closed boom or at 2 ton (4000 lb) position is 48 inches (1.22 m) and with a fully extended boom or at 1/2 ton (1000 lb) position is 99 inches (2.5 meters) from the ground to the bottom of the hook. The hoist has got a steel chain and a grab hook at the end of the boom, where lifting chains, slings or a load leveler can be mounted for lifting loads.

Advantages

- Great price, one of the cheapest 2 ton (4000 lb) engine hoists on the market

- Foldable design allows saving space when storing the tool

- Stable and easy to manoeuvre thanks to 6 swivel casters

Disadvantages

- Does not have the highest quality construction when compared to more expensive 2 ton (4000 lb) hoists from well known manufacturers

- Hoist can be hard to push when under a load, also it does not come with a push handle